Epoxy Injection Molding Developments and Changes

Epoxy Injection Molding Developments and Changes

Blog Article

Discover the Different Usages and Advantages of Epoxy Shot Molding in Modern Production

Epoxy shot molding is changing the means you assume regarding production. By utilizing the special residential or commercial properties of epoxy resins, this procedure provides resilient and accurate parts with remarkable effectiveness. You may be amazed to discover how it's being used in industries such as vehicle and aerospace. As we discover its advantages and applications, you'll find why this technique is becoming important in contemporary production methods. What makes it so cutting edge?

Comprehending Epoxy Injection Molding

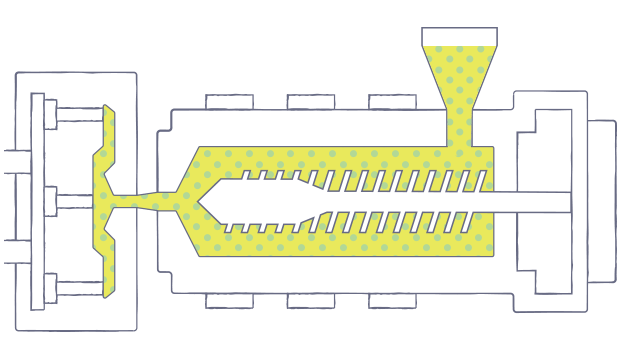

You'll find it's a highly effective process for developing accurate and long lasting parts when you discover epoxy shot molding. This technique uses warmed epoxy material, which you inject right into a mold under pressure, enabling it to fill up every detail. The result? Top notch elements that satisfy specific specifications.You'll discover that the process is excellent for creating complicated geometries, making it a popular selection in numerous industries, including automotive, aerospace, and electronics. Epoxy injection molding likewise provides outstanding surface area coatings, which can minimize the requirement for extra finishing processes.Moreover, it enables for fast manufacturing, helping you fulfill limited due dates without sacrificing quality. Understanding this procedure equips you to harness its abilities successfully, making your production procedures much more competitive. By going with epoxy injection molding, you can attain the precision and sturdiness your tasks require, guaranteeing your products stand the examination of time.

Key Benefits of Epoxy Resins

Though epoxy materials include a variety of advantages, their extraordinary toughness and toughness stand out one of the most. You'll discover that these materials can hold up against extreme conditions, making them ideal for demanding applications. Their chemical resistance is one more essential advantage; they withstand solvents, acids, and moisture, making sure durability in various environments.When you make use of epoxy, you're additionally obtaining exceptional bond homes, enabling them to bond successfully with various products. This convenience suggests you can produce solid, reputable products using less product, which can save you money in the lengthy run.Additionally, epoxy resins cure quickly, which speeds up manufacturing times. You will not have to wait long to see results, assisting you meet limited target dates. Ultimately, their aesthetic coating can enhance the look of your products, giving them a polished look that allures to consumers. Generally, epoxy materials supply a powerful combination of efficiency and value.

Applications in the Automotive Industry

As the auto industry remains to develop, epoxy shot molding plays a vital duty in improving vehicle performance and toughness. You'll find that epoxy resins are utilized in numerous auto elements, from structural parts to aesthetic surfaces. Their outstanding attachment residential properties ensure that various materials bond successfully, which is essential for creating lightweight yet solid components.Additionally, epoxy injection molding permits intricate geometries, making it possible for producers to design detailed parts that boost the rules of aerodynamics and decrease weight. This not only increases gas efficiency yet likewise adds to total lorry safety.Moreover, the chemical resistance of epoxy makes it ideal for components revealed to extreme settings, such as engine components and gas systems. By incorporating epoxy shot molding into production, you're making certain that cars are not just trustworthy but additionally geared up for the needs of modern-day driving. This modern technology really represents a significant advancement in automobile production.

Aerospace Innovations With Epoxy Shot Molding

Epoxy shot molding is changing the aerospace market by supplying lightweight, long lasting elements that enhance aircraft efficiency. You'll locate that this innovation allows producers to develop complex designs and complicated shapes, which are necessary in maximizing the rules of aerodynamics. By utilizing epoxy, you're taking advantage of its excellent thermal and chemical resistance, making it excellent for different aerospace applications.Imagine the possibility of using epoxy in components like wing structures or body components. Not just does it reduce weight, yet it likewise adds to improved fuel effectiveness. You'll appreciate just how this technology results in longer flight arrays and reduced operational costs for airlines.Additionally, the precision used by epoxy injection molding assurances that each part meets rigorous aerospace criteria, improving safety and security and integrity. As the market remains to innovate, you'll see epoxy injection molding play a pivotal role in the future of aerospace innovation, driving improvements that make flight much safer and more effective.

Enhancing Item Toughness and Stamina

When you select epoxy shot molding, you're increasing your products' toughness and strength substantially. With enhanced impact resistance and improved adhesion buildings, your items can stand up to more damage. And also, the temperature level and chemical stability of epoxy warranties that they keep honesty even in extreme conditions.

Enhanced Effect Resistance

Enhanced effect resistance is just one of the standout advantages of epoxy injection molding, making your products not only a lot more long lasting but additionally considerably stronger. You're spending in elements that can stand up to heavy lots and resist damage from external pressures when you select epoxy shot molding. This boosted strength indicates less product failings and longer life expectancies, eventually saving you money on replacements and fixings. Whether you're creating automobile components or consumer items, the capacity to absorb shocks without fracturing or damaging is necessary. Your items will certainly perform better popular environments, providing you an one-upmanship. By focusing on impact resistance in your styles, you'll ensure your items can handle whatever challenges come their means, boosting your general reputation in the market.

Boosted Bond Residences

Strong bond residential properties substantially boost the sturdiness and strength of your items. When you make use of epoxy injection molding, you're making sure that the products bond efficiently, which minimizes the risk of delamination or splitting up gradually. This implies your end products can withstand better anxieties and pressures, making them appropriate for demanding applications.Moreover, improved attachment decreases the possibility of issues or failures, leading to higher client contentment. With stronger bonds, your items keep their integrity even under extreme conditions, leading to longer life-spans and minimized need for substitutes. Inevitably, purchasing epoxy shot molding not just improves the efficiency of your things yet likewise strengthens your brand online reputation for high quality and reliability. You'll discover the distinction in toughness and toughness.

Temperature and Chemical Stability

Temperature level and chemical stability are crucial factors that significantly enhance the durability and strength of your items. By making use of epoxy shot molding, you produce components that endure severe temperatures and resist chemical degradation. This means your products keep their stability in severe atmospheres, whether they're revealed to high heat or destructive materials. The durable nature of epoxy warranties that your things don't warp or break down, extending their life-span considerably. On top of that, this stability converts right into reduced upkeep prices and fewer replacements, which is a win for your profits. With epoxy, you're not just creating products; you're purchasing resilient services that meet the needs of contemporary manufacturing. Accept these advantages, and enjoy your items flourish in competitive markets.

Minimizing Waste and Improving Efficiency

As you discover the advantages of epoxy injection molding, you'll find that decreasing waste and enhancing efficiency work together. This process decreases material waste by utilizing accurate quantities of epoxy, guaranteeing you get the most from your resources. With careful control, you can stay clear of excess product, bring about cost financial savings and less environmental impact.Moreover, epoxy injection molding boosts performance by enhancing production cycles. The quick curing times of epoxy enable faster turnaround, suggesting you can produce more parts in less time. This not just increases your outcome however likewise reduces lead times for your customers.Additionally, the sturdiness and stamina of epoxy parts reduce the requirement for frequent substitutes, better reducing waste. By choosing epoxy injection molding, you're not simply improving your processes, but you're also adding to a more lasting manufacturing atmosphere.

Future Trends in Epoxy Injection Molding

As you look in advance on the planet of epoxy shot molding, you'll see interesting advancements visit this site on the horizon. Innovations in products, increased automation, and a more powerful focus on sustainability are established to improve the sector. These fads promise not just to boost efficiency however additionally to decrease environmental effect, making the future of producing brighter than ever before.

Advanced Material Innovations

While the epoxy shot molding sector has long been understood for its longevity and versatility, current advancements in material technologies are readied to revolutionize its applications. You'll locate that new formulations are improving buildings like heat resistance, chemical stability, and effect strength. These renovations permit for the production of lighter, more reliable parts without compromising integrity. Furthermore, bio-based epoxy options are emerging, providing to ecologically mindful production techniques. You can also check out making use of nanomaterials that even more improve efficiency qualities, allowing you to create items that meet rigid market standards. As these sophisticated products end up being extra accessible, you'll be positioned to utilize them, boosting your item offerings and remaining in advance in an open market.

Automation and Performance

With the quick rate of technical advancements, automation is ending up being a game-changer in epoxy shot molding. By integrating automated systems, you can considerably improve production speed and lower human error. Robotics can take care of recurring tasks, guaranteeing uniformity in high quality and precision Our site while freeing your team to concentrate on even more intricate problems. Automated surveillance systems likewise supply real-time information, permitting prompt modifications to maximize the procedure. As you execute these innovations, you'll see improved efficiency, lower manufacturing costs, and faster time-to-market for your items. Accepting automation not just streamlines procedures yet additionally positions your organization to react promptly to market demands, keeping you competitive in the ever-evolving manufacturing landscape.

Sustainability in Manufacturing

The integration of automation in epoxy injection molding sets the phase for a more powerful concentrate on sustainability in production. By employing innovative technologies, you can reduce waste and power consumption in the production procedure. Automated systems improve procedures, enabling for extra precise product usage and decreased excess - epoxy injection molding.Additionally, making use of eco-friendly epoxy solutions gets on the increase, as makers look for to develop much less unsafe items. This change not just benefits the environment however additionally interest consumers who focus on sustainability.As you welcome these future patterns, you'll discover that sustainable practices enhance your brand name image and can lead to set you back financial savings gradually. Inevitably, concentrating on sustainability in epoxy injection molding will position you as a leader in responsible production

Often Asked Questions

How Does Epoxy Injection Molding Compare to Traditional Molding Methods?

Epoxy shot molding offers better accuracy and toughness contrasted to standard techniques. You'll locate it creates stronger parts with much less waste, permitting complex layouts that satisfy requiring specifications without sacrificing high quality or effectiveness.

What Safety Preventative Measures Should Be Taken When Making Use Of Epoxy Resins?

Can Epoxy Shot Molding Be Made Use Of for Personalized Layouts?

Yes, you can definitely utilize epoxy injection molding for customized designs. It enables complex shapes and accurate describing, making it suitable for creating distinct components tailored to your certain needs and applications.

For how long Does the Epoxy Curing Process Typically Take?

The epoxy treating procedure usually takes concerning 24 to 72 hours, depending on the details solution and environmental conditions - epoxy injection molding. You'll intend to ensure suitable temperature and humidity for the finest outcomes during curing

What Is the Cost-Effectiveness of Epoxy Injection Molding?

Epoxy injection molding's cost-effectiveness comes from its sturdiness and very little waste. You'll discover that it lowers manufacturing expenses in time, allowing you to create premium items without damaging your spending plan or sacrificing performance. As Get More Information the automobile market proceeds to progress, epoxy shot molding plays a vital function in enhancing vehicle performance and resilience. Epoxy injection molding is revolutionizing the aerospace market by providing light-weight, sturdy elements that boost airplane efficiency. By utilizing epoxy, you're benefiting from its exceptional thermal and chemical resistance, making it optimal for different aerospace applications.Imagine the potential of utilizing epoxy in parts like wing structures or body parts. When you select epoxy injection molding, you're increasing your items' resilience and strength substantially. Improved influence resistance is one of the standout benefits of epoxy injection molding, making your products not just a lot more durable however additionally considerably stronger.

Report this page